FlexyPlant – Customised solutions for kilo lab automation

Project planning – implementation – commissioning

- FlexySys is an automation concept developed specifically for chemical process research

- The FlexySys process control system combines the flexibility of manual operation with the safety, reliability and reproducibility of a recipe-controlled plant

- Also suitable for special problem situations in chemical process technology, e.g. polymerisation, hydrogenation and the thermal separation of substances

Competence through many years of practical experience in the production of chemicals

Where is FlexyPlant used?

- FlexyPlant is our response to the particular demands imposed on the automation of kilo lab and pilot plants.

- Firstly the amounts of materials used require almost the level of process management of a production operation, together with a suitable safety concept. Secondly the operating team must be able to respond quickly and flexibly to deviations from the expected course of events.

Drawing up the specifications

- Plant specifications are drawn up in close collaboration with the end user.

- At SYSTAG the client will meet contact persons who know the working procedure and requirements of process development from their own professional experience. Thanks to the shared language, the result is a clear, detailed specification.

An overview of FlexyPlant

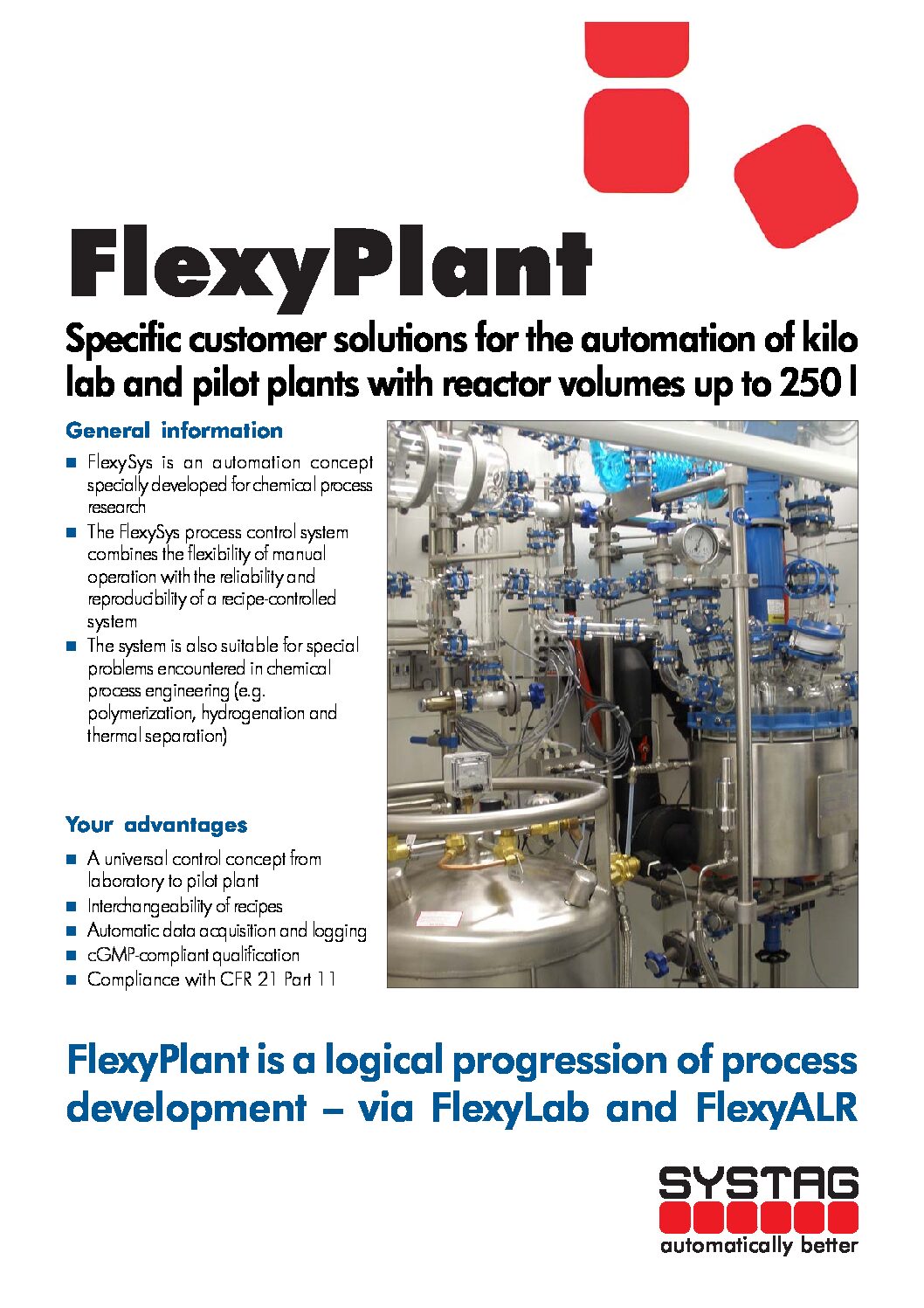

- Customised solutions for the complete automation of kilo lab plants with reactor sizes up to 250 litres

- Total turn-key solutions (plants, sensors and fittings) in collaboration with proven partners

- Consistent «Look and Feel» of the control systems – from FlexyCUBE (multi-gram) via laboratory scale-up (FlexyPAT) to multi-kilogram plants

- Automation of special apparatus, e.g. rectification units, hydrogenation autoclaves, polymerisation plants etc.

Your gain

- Consistent operating concept from laboratory to pilot plant

- Automatic data capture and reporting

- Qualification in compliance with cGMP

- Conforms to CFR 21 Part 11